- Cordless Drill

- Cordless Impact Drill

- Cordless Impact Wrench

- Cordless Ratchet Wrench

- Cordless Impact Driver

- Cordless Screwdriver

- Cordless Hammer Drill

- Cordless Angle Grinder

- Cordless Circular Saw

- Cordless JigSaw

- Reciprocating Saw

- Laser Level

- Cordless Polishers

- Cordless Pressure Washer

- Cordless Heat Gun

- Cordless Spray Gun

- Lithium Battery & Charger

- Power Tool Set

Types of Chainsaw Blades: How to Choose the Right One | CISIVIS

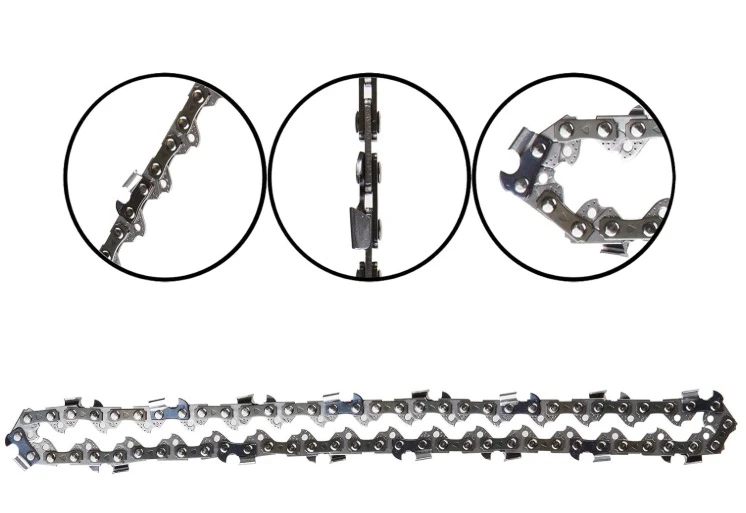

The performance of a chainsaw depends heavily on its chain — the true cutting element of the tool.

Choosing the right chain determines how fast, smooth, and safely your saw will cut.

A well-matched chain can make a small electric saw feel powerful, while a poor match can waste energy and wear out parts quickly.

Whether you’re a home gardener or a professional logger, understanding chain types and specs helps you get the best results.

In this guide, CISIVIS explains everything you need to know about chainsaw chains — from key parameters and chain types to how to choose and maintain them.

Key Chainsaw Chain Parameters

Before selecting a new chain, it’s essential to understand the technical parameters that define its compatibility and cutting behavior.

Each parameter affects how efficiently the saw performs and how the chain interacts with wood.

Pitch

Pitch is the average distance between three consecutive rivets, divided by two.

It determines the overall size of the chain and how deep each tooth bites into the wood.

Common pitch sizes include 1/4", .325", 3/8", and .404".

- 1/4" pitch: small and lightweight, found on compact pruning or electric saws.

- .325" pitch: provides a balance between smoothness and speed, ideal for mid-size saws up to 50cc.

- 3/8" pitch: heavier and more aggressive, used on 50–70cc saws and professional-grade models.

- .404" pitch: large, robust chains for industrial and forestry use.

A larger pitch means each cutter removes more material per pass, which increases cutting speed but also demands more torque and power.

For electric chainsaws or lower-horsepower engines, .325" is usually the sweet spot between performance and control.

Comparison: .325" vs 3/8" Chains

| Chain Type | Cutting Speed | Vibration | Recommended Use | Power Requirement |

|---|---|---|---|---|

| .325" | Moderate | Low | Mid-size electric or gas chainsaws | Low–Medium |

| 3/8" | Fast | Higher | Professional or heavy-duty work | Medium–High |

Summary:

.325" chains are smoother, quieter, and easier to control, while 3/8" chains cut faster and bite deeper — ideal for professional or high-power saws.

Gauge

Gauge measures the thickness of the drive links — the parts that fit inside the guide bar groove.

The gauge must match the bar groove width precisely. Even a small mismatch can cause chain slippage, premature wear, or failure to stay on the bar.

Common gauges include .043", .050", .058", and .063".

- Thin gauges (.043", .050") reduce friction and work well for cordless or compact saws.

- Thicker gauges (.058", .063") provide better stability during long or heavy cuts and resist bar flexing.

Gauge affects durability, stability, and vibration control, not necessarily cutting speed.

Professional users often prefer thicker chains for reliability, while DIY users benefit from the efficiency of thinner designs.

Drive Link Count

Drive Link Count indicates how many drive links the complete chain loop contains.

This determines the total chain length and must match both your guide bar and sprocket setup.

A chain that’s too short won’t fit; too long and it can’t maintain proper tension.

Most guide bars are marked with all three key specs — pitch, gauge, and drive link count — which you should always check before replacement.

For example, a 16-inch bar typically requires around 66 drive links, depending on the pitch and gauge combination.

Cutter Type & Sequence

The cutter type defines the shape of the cutting teeth, while the sequence describes their spacing pattern.

Both affect cutting aggressiveness, chip removal, and vibration.

Cutter Types:

- Full Chisel: square-cornered teeth for fast, aggressive cutting of clean hardwood. Sharp but dulls quickly.

- Semi Chisel: round-cornered teeth that cut slower but stay sharp longer in dirty or mixed wood.

- Low-Kickback: includes depth limiters that prevent the chain from “grabbing” too much wood — safer for beginners.

Tooth Sequences:

- Full Comp (Standard): every drive link has a cutter tooth, providing smooth cutting and clean finishes.

- Skip Chain: teeth are spaced further apart, improving chip clearance and reducing drag on long bars.

Lubrication and Design Features

Proper lubrication is essential for chain longevity and consistent performance.

High-end chains, such as those in the CISIVIS Performance Series, include oil reservoirs or lubrication channels on each drive link.

These distribute oil evenly along the bar, reducing friction and heat buildup.

Some modern chains also feature chrome-hardened teeth and anti-vibration tie straps, improving both durability and user comfort.

Keeping your chain clean, properly tensioned, and well-lubricated is the simplest way to extend the life of your entire cutting system.

Main Chainsaw Chain Types

Full Chisel Chain

Uses sharp, square-cornered teeth that slice through wood fibers quickly and efficiently.

Best for clean hardwood and professional cutting tasks.

However, it dulls faster when exposed to dirt or bark.

Best for: professional users

Pros: fast cutting speed

Cons: dulls quickly, higher kickback risk

Semi Chisel Chain

Has slightly rounded corners that provide smoother, more forgiving cutting.

It tolerates dirt and mixed wood better and stays sharp longer.

Best for: general homeowners and gardeners

Pros: durable, low maintenance

Cons: slower cutting speed

Low-Kickback Chain

Designed with safety in mind, these chains include guard links that limit cutting depth and reduce the risk of kickback.

Perfect for beginners or safety-focused users.

Best for: beginners and electric saw users

Pros: safer, easier control

Cons: less aggressive cutting

How to Choose the Right Chainsaw Chain

Choosing a chain comes down to bar length, saw power, and cutting environment.

Match the Bar Length

| Bar Length | Typical Use | Characteristics |

|---|---|---|

| 10-inch | Light pruning and trimming | Compact, quiet, easy to control |

| 18-inch | General cutting and yard maintenance | Balanced between speed and control |

| 20-inch | Forestry and heavy-duty work | Deep cuts, higher power demand |

Match the Saw’s Power

- Low-power saws: .325" semi chisel chain

- Mid-power saws: 3/8" semi chisel or low-kickback chain

- High-power saws: 3/8" full chisel chain for maximum cutting speed

Match the Environment

- Dirty or bark-heavy wood: semi chisel for durability

- Clean hardwood: full chisel for speed

- Safety priority: low-kickback for stable control

Not sure which chain fits your saw?

Contact CISIVIS and our engineers will help you find the right model — free of charge.

Chain Maintenance and Replacement

A sharp chain not only cuts faster but also prevents overheating and excessive wear.

Replace or re-sharpen the chain when you notice:

- Smoke or excessive heat during cutting

- Rough or uneven cut surfaces

- Frequent chain loosening

- Multiple sharpenings with no improvement

Even if chains look similar, pitch and gauge mismatches can make them incompatible.

Always check the bar markings before ordering a new chain.

Common Questions

Q1: How often should I replace my chain?

After 3–5 full sharpenings or when cutting performance drops significantly.

Q2: Can I use a longer chain than my original bar?

No. Chain length must match the bar exactly to avoid slipping or safety risks.

Q3: Which chain works best for hardwood vs softwood?

- Hardwood: Full chisel chain

- Softwood or mixed wood: Semi chisel chain

About CISIVIS & Conclusion

In summary:

Understanding chain parameters and types is the key to better cutting performance and tool longevity.Full chisel chains deliver speed, semi chisel chains deliver durability, and low-kickback chains deliver safety.

Choose wisely — and let CISIVIS keep your cutting experience efficient, safe, and reliable.

WHY YOU CAN TRUST CISIVIS

CISIVIS has over 6 years of experience in power tool R&D, delivering high-quality solutions worldwide. Our 3,000 m² factory, equipped with advanced machinery and strict quality control, ensures precision, efficiency, and a daily output of over 10,000 units for reliable bulk order fulfillment.

Our product portfolio includes a full range of power tools, including cordless drills, impact drills, impact wrenches, angle grinders, circular saws, jigsaws, chainsaws, lawn mowers, car washers, laser levels, cordless trimmers, polishers, paint sprayers, heat guns, and more. We also offer OEM/ODM services to meet diverse market needs.