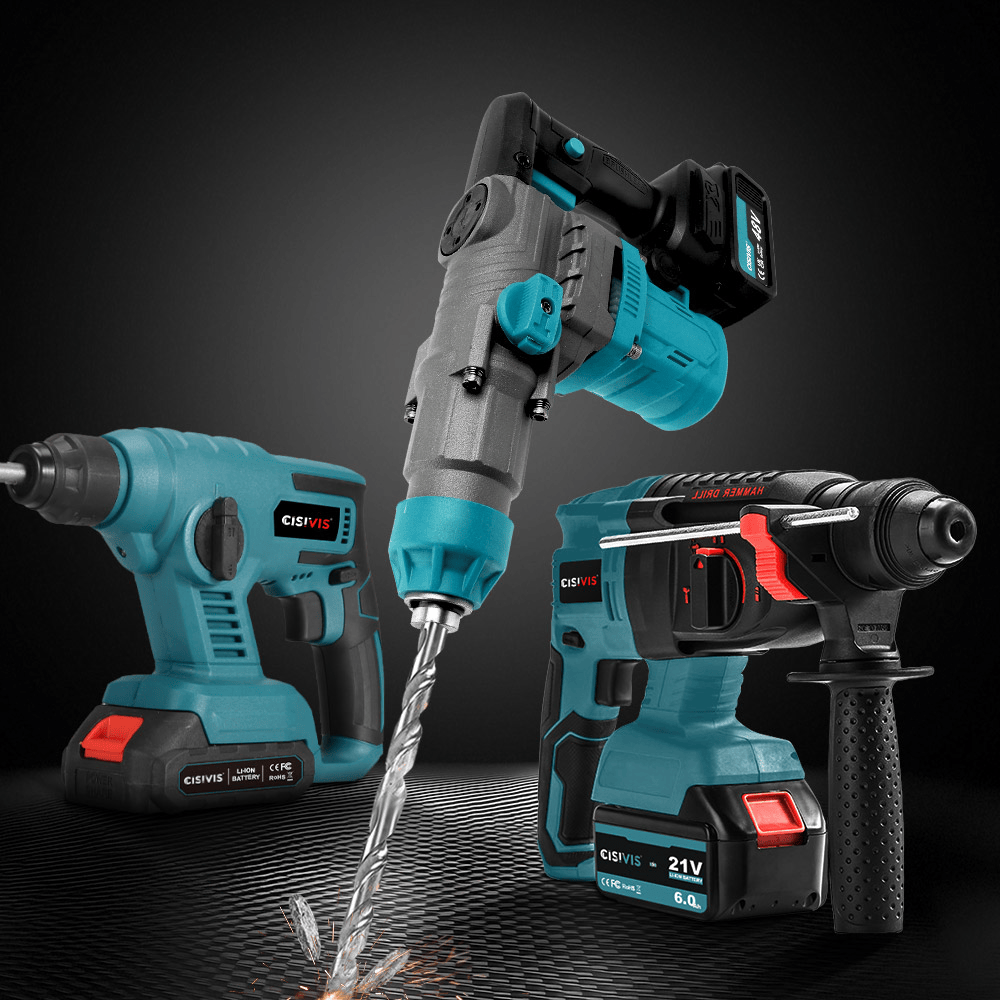

- Cordless Drill

- Cordless Impact Drill

- Cordless Impact Wrench

- Cordless Ratchet Wrench

- Cordless Impact Driver

- Cordless Screwdriver

- Cordless Hammer Drill

- Cordless Angle Grinder

- Cordless Circular Saw

- Cordless JigSaw

- Reciprocating Saw

- Laser Level

- Cordless Polishers

- Cordless Pressure Washer

- Cordless Heat Gun

- Cordless Spray Gun

- Lithium Battery & Charger

- Power Tool Set

Good cordless drill for construction and industrial use

Cisivis cordless drill set Solve Problems

For contractors, industrial buyers, and facility managers, efficiency is the top priority. In B2B projects, more downtime means higher costs—and delayed schedules hurt overall business performance. Traditional corded drills limit mobility, while underpowered tools can’t handle demanding work environments. The right cordless drill for construction and industrial use solves these issues by combining power, mobility, and reliability.

CISIVIS offers good cordless drills,which are built for professional teams that need dependable solutions for construction, industrial maintenance, and large-scale outdoor projects. With multiple voltage options, they fit different work scenarios and reduce operational stress.

Light Construction and Furniture Assembly

Scenario:

Office fit-outs, furniture workshops, and retail installations often require fast drilling and fastening. Workers need clean holes in wood panels, quick fixture assembly, and efficient shelving installation.

For example, a furniture factory in Eastern Europe cut assembly time by 15% after switching from corded drills to CISIVIS 16.8V cordless drills, thanks to better mobility on production lines.

Pain Points:

Extension cords slow down workflow and create safety hazards.

Low-power drills cannot sustain repetitive fastening.

Heavy drills lead to worker fatigue during long shifts.

Best Choice: 16.8V CISIVIS Cordless Drill for Light Work

Compact and lightweight, perfect for assembly lines.

Reliable torque for wood, MDF, and drywall screws.

Cordless mobility improves productivity in fast-paced work environments.

| Brushed and Brushless | Brushless |

| Battery Capacity | 45Nm |

| Max Torque | 1.3Ah |

| No-load RPM | 0-450rpm-1800rpm |

Comparison:

18V Drill: More powerful but heavier for all-day indoor work.

Corded Drill: Steady power but limited mobility.

Medium to Heavy Construction Sites

Scenario:

On residential and commercial construction sites, contractors drill through hardwood, steel studs, and masonry walls across large job areas. Mobility and strong torque are critical to stay on schedule.

For example, a contractor in Southeast Asia reduced project delays by 20% after adopting CISIVIS 18V cordless power drills, eliminating the need for extension cords and multiple power outlets.

Pain Points:

Corded drills limit worker movement and require multiple outlets.

Weak tools cannot handle masonry or steel drilling.

Delays cause labor costs to rise and reduce profitability.

Best Choice: 18V CISIVIS Cordless Drill for Contractors

Delivers strong torque for wood, steel, and concrete.

Long-lasting battery supports mobility across job sites.

Rugged design withstands heavy use by professional crews.

Comparison:

12V Drill: Lightweight but insufficient for heavy-duty materials.

Gas-powered Drill: Strong but noisy, difficult to handle indoors.

Industrial Maintenance and Equipment Servicing

Scenario

Factories and machine shops require reliable drills for servicing equipment, retrofits, and steel fabrication. Tools must work in tight spaces and handle continuous use without overheating.

For example, a machinery plant in South America improved maintenance efficiency by 25% using CISIVIS 21V brushless cordless drills, cutting downtime on production lines.

Pain Points:

Corded drills are difficult to use in tight areas.

Old brushed models overheat during continuous use.

Equipment downtime impacts factory output and efficiency.

Best Choice: Brushless 21V Industrial Cordless Drill

Brushless motor ensures longer battery life and reduced wear.

Compact size fits confined industrial spaces.

Delivers stable torque for steel plates, frames, and machine repairs.

| Brushed and Brushless | Brushless |

| Battery Capacity | 110Nm |

| Max Torque | 1.5Ah |

| No-load RPM | 0-2200rpm |

Comparison:

Brushed Drills: Less efficient, shorter life cycle.

Corded Drills: Reliable but bulky for modern industrial setups.

Multi-Material and Large-Scale Projects

Scenario:

Commercial renovations and facility upgrades demand versatile drills that work on wood, plastics, concrete, and metals. Teams need fewer tool changes and simplified inventory management.

For example, a renovation company in North America reduced tool inventory by 30% after adopting CISIVIS dual-speed 18V cordless drill kits for multi-material projects.

Pain Points:

Using multiple tools slows down projects.

Storage and inventory costs rise with too many tools.

Inconsistent tool selection may damage materials.

Best Choice: Dual-Speed 18V Cordless Drill Kit

Includes multiple drill bits for wood, metal, and masonry.

Adjustable speed control ensures precision and safety.

Reduces the need for tool changes and simplifies inventory.

Comparison:

Single-Speed Drills: Lack flexibility for mixed materials.

12V Drills: Too weak for large, heavy-duty projects.

Outdoor and Landscaping Applications

Scenario

Landscaping contractors and public works teams often work in wide outdoor areas with no power outlets. They need durable, portable drills for long shifts in rough environments.

For example, a landscaping crew in the Middle East completed fencing projects 18% faster using CISIVIS 18V cordless drills, compared with gas-powered alternatives.

Pain Points:

Lack of power outlets in large outdoor areas.

Tools must endure long shifts in rough environments.

Workers need portability to cover wide spaces efficiently.

Best Choice: 18V CISIVIS Cordless Drill for Outdoor Projects

Cordless freedom allows unrestricted mobility.

Strong torque for wood, composites, and outdoor fixtures.

Long battery runtime for full-day projects in the field.

Comparison:

Gas-powered Drills: High power but noisy and less precise.

Lower Voltage Drills: Too weak for outdoor tasks.

Why B2B Buyers Choose CISIVIS Cordless Drills

Professional reliability: Built for heavy daily use in demanding industries.

Wide adaptability: Options available for light, heavy, industrial, and outdoor applications.

Cost efficiency: Reduces downtime, saves labor hours, and supports large-scale projects.

For B2B buyers, choosing the right cordless drill means better performance, lower costs, and stronger results. With CISIVIS cordless drills, businesses gain dependable tools to handle real-world challenges.

FAQ

Which cordless drill is best for contractors on heavy construction projects?

The 18V CISIVIS cordless drill for contractors provides the torque needed for masonry, steel, and large-scale construction tasks.

Is a 12V cordless drill suitable for B2B buyers?

Yes, but it is best for light applications such as furniture assembly, office installations, and workshop production lines.

Why should industrial buyers choose a brushless 20V cordless drill?

Brushless models provide longer life, steady torque, and higher efficiency. They are ideal for factories, machine shops, and continuous industrial use.

Can CISIVIS cordless drills be purchased in bulk for international buyers?

Yes, CISIVIS offers wholesale supply, OEM/ODM services, and competitive pricing for B2B clients worldwide.

How do cordless drills improve efficiency compared to corded drills?

Cordless drills offer mobility, flexibility, and time savings. They reduce downtime on job sites by removing the need for power outlets and extension cords.

Final Call-to-Action

CISIVIS cordless drills deliver solutions for construction, maintenance, industrial facilities, and outdoor projects. Whether you need a 12V drill for light work or a 20V brushless model for industrial use, CISIVIS provides professional-grade performance tailored to B2B clients.

Explore CISIVIS Cordless Drills for Your Business →