- Cordless Drill

- Cordless Impact Drill

- Cordless Impact Wrench

- Cordless Ratchet Wrench

- Cordless Impact Driver

- Cordless Screwdriver

- Cordless Hammer Drill

- Cordless Angle Grinder

- Cordless Circular Saw

- Cordless JigSaw

- Reciprocating Saw

- Laser Level

- Cordless Polishers

- Cordless Pressure Washer

- Cordless Heat Gun

- Cordless Spray Gun

- Lithium Battery & Charger

- Power Tool Set

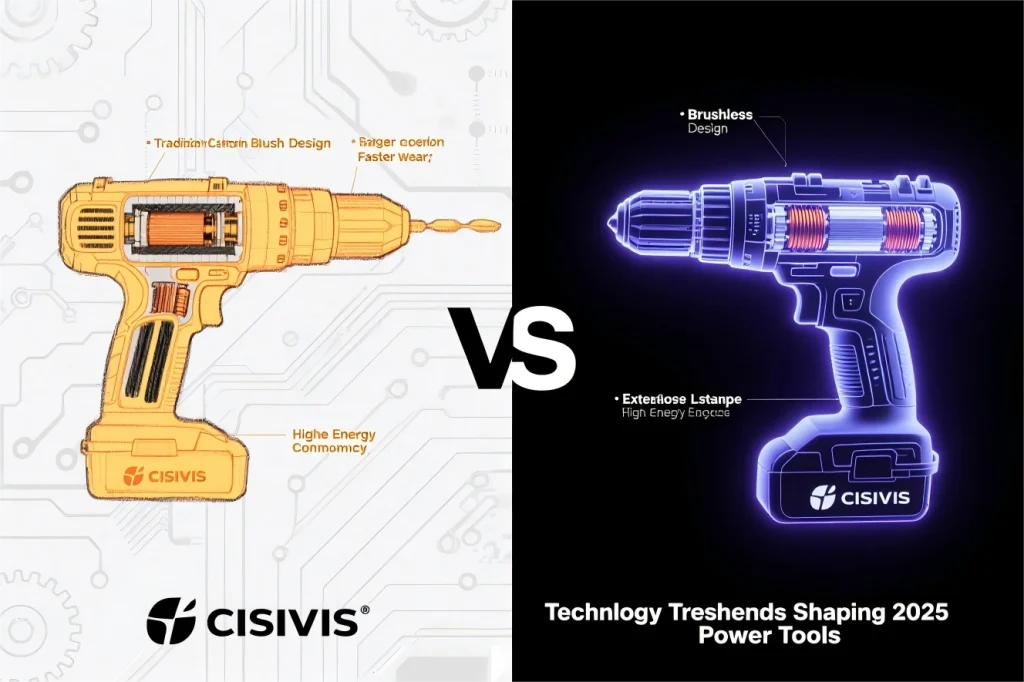

Brushed vs Brushless Cordless Drill: Which One Should You Buy in 2025?

Introduction: Why the Debate Matters

Choosing the right cordless drill can be confusing. Brushed drills are affordable and reliable for DIY projects, while brushless drills offer higher efficiency and durability for professional use. This guide helps you compare brushed vs brushless cordless drills in 2025, so you can decide which model fits your needs—whether you are a homeowner, contractor, or distributor.

This article explores the differences between brushed and brushless cordless drills, analyzes how CISIVIS product lines align with global industry trends, and provides insights to help B2B buyers make smarter decisions.

Brushed Cordless Drill: Pros, Cons, and Best Uses

For decades, brushed motors have powered cordless drills, offering a stable and cost-effective solution. Their biggest advantages are affordability, easy servicing, and suitability for lighter workloads.

B2B buyers such as retail chains or procurement managers for DIY-focused brands often choose brushed cordless drills when targeting entry-level consumers or cost-sensitive markets.

CISIVIS Example

The Brushed Cordless Drill 25Nm 10mm remains a strong choice for B2B buyers who serve the homeowner segment. Its compact design, reliable torque, and affordable positioning make it an ideal SKU for distributors targeting DIY stores and e-commerce platforms.

- Corded or Cordless:Cordless

- Brushed and Brushless:Brushed

- Battery Voltage:21V

- Max Torque:25Nm

- No-load RPM:0-450/0-1600r/min

Brushless Cordless Drill: Why Professionals Prefer It

The brushless cordless drill has rapidly become the preferred option for professional contractors and industrial applications. By eliminating friction-based brushes, these motors reduce wear, extend lifespan, and deliver consistent torque with higher energy efficiency.

CISIVIS Example

The Brushless Cordless Drill 21V 110Nm is designed for heavy-duty users who demand long runtimes, robust torque output, and reduced maintenance. B2B buyers serving professional markets—such as contractors, facility management suppliers, and global distributors—gain a strong competitive edge by offering high-performance brushless options.

- Corded or Cordless:Cordless

- Brushed and Brushless:Brushless

- Battery Voltage:21V

- Max Torque:110Nm

- No-load RPM:0-2200rpm

Corded Drills: Are They Still Worth Buying in 2025?

Even as cordless drills dominate the headlines, corded tools continue to hold a stable market share in 2025, especially in cost-sensitive or power-demanding environments.

CISIVIS Example

The 10mm 550w Corded Aluminum Head Electric Drill demonstrates why corded models remain relevant. With steady power delivery, compact size, and durability, it is ideal for buyers in regions where battery infrastructure is expensive or limited.

- Corded or Cordless:Corded

- Motor Power:550W

- Battery Voltage:100-240V

- Weight:1.95KG

- No-load RPM:0-2800R/min

For B2B buyers, offering a balanced portfolio of corded and cordless options remains essential to address different market tiers.

Regional Drill Trends 2025: Which Markets Prefer Brushed, Brushless, or Corded?

- North America: Rising demand for brushless cordless drills among contractors and home improvement retailers, driven by efficiency standards.

- Europe: Strong focus on sustainability; lithium-ion brushless cordless drills are favored for reduced energy waste and compliance with green regulations.

- Asia-Pacific: Mixed adoption; brushed cordless drills dominate in price-sensitive retail channels, while brushless gains traction in infrastructure projects.

- Latin America & Middle East: Corded drills maintain strong relevance due to lower upfront cost and less reliance on advanced battery ecosystems.

By aligning product offerings with regional preferences, B2B distributors maximize relevance and capture untapped demand.

Choosing the Right Drill: How to Balance Cost, Performance, and Market Needs

Rather than asking which is “better,” the true question for B2B buyers is: Which product mix drives the most market coverage and profitability?

- Brushed Cordless Drill: Best suited for cost-conscious consumers, DIY stores, and regions with limited purchasing power.

- Brushless Cordless Drill: Ideal for professional markets, contractors, and distributors targeting high-margin customers.

- Corded Drill: A reliable fallback option in developing markets or specialized industries requiring constant power.

This balance allows B2B buyers to cover multiple segments, ensuring flexibility in pricing strategies and higher sales volumes.

CISIVIS Drill Innovations: Smarter, More Durable, and Efficient Tools

CISIVIS invests in both brushed and brushless technologies, combining proven reliability with forward-looking design. Key innovation areas include:

- Enhanced Brushless Motor Efficiency: Optimized torque delivery with smarter power management.

- Improved Brushed Models: Upgraded materials to reduce wear and extend product lifecycle.

- Sustainable Design: Integration of recyclable components and battery systems with longer lifespans.

- Smart Control Features: Variable speed triggers and digital displays for precise applications.

By continuously investing in R&D, CISIVIS enables B2B buyers to offer not just tools, but solutions aligned with industry trends.

Drill in Action: Real-World Use Cases and Buyer Insights

- A European distributor added the Brushless Cordless Drill 21V 110Nm to their portfolio and saw a 30% increase in sales to professional contractors.

- A Latin American retailer continued to stock the 10mm 550w Corded Aluminum Head Electric Drill, maintaining steady sales with entry-level DIY buyers.

- An Asian e-commerce wholesaler bundled the Brushed Cordless Drill 25Nm 10mm as a “starter kit” for homeowners, increasing customer acquisition in price-sensitive markets.

These examples show how product diversity supports different buyer needs while strengthening overall competitiveness.

Partner with CISIVIS

Even as cordless drills dominate the headlines, corded tools continue to hold a stable market share in 2025, especially in cost-sensitive or power-demanding environments.

CISIVIS Example: The 10mm 550w Corded Aluminum Head Electric Drill demonstrates why corded models remain relevant. With steady power delivery, compact size, and durability, it is ideal for buyers in regions where battery infrastructure is expensive or limited.

For B2B buyers, offering a balanced portfolio of corded and cordless options remains essential to address different market tiers.

FAQ

What is the best cordless electric drill for B2B buyers?

The answer depends on your market. For professional use, a brushless cordless drill like the CISIVIS 21V 110Nm offers durability and performance. For entry-level DIY buyers, the 25Nm brushed cordless drill balances cost and function.

Why is a brushless motor cordless drill more efficient?

Because it eliminates friction between brushes and commutators, delivering more power, longer life, and better energy use—ideal for buyers who value long-term ROI.

Is there still demand for good cordless drill models with brushed motors?

Yes. Brushed cordless drills remain relevant in markets where price is the top priority. Retailers and distributors often stock them for first-time buyers or promotional bundles.

What makes the best brushless power drill stand out in 2025?

It combines efficiency, sustainability, and smart controls, aligning with global industry trends and giving B2B buyers a competitive sales edge.

Should B2B buyers still stock corded drills?

Yes. Corded drills remain important in regions with high electricity access but limited battery adoption, offering consistent power at a lower cost.