- Cordless Drill

- Cordless Impact Drill

- Cordless Impact Wrench

- Cordless Ratchet Wrench

- Cordless Impact Driver

- Cordless Screwdriver

- Cordless Hammer Drill

- Cordless Angle Grinder

- Cordless Circular Saw

- Cordless JigSaw

- Reciprocating Saw

- Laser Level

- Cordless Polishers

- Cordless Pressure Washer

- Cordless Heat Gun

- Cordless Spray Gun

- Lithium Battery & Charger

- Power Tool Set

How to Measure a Chainsaw

When purchasing or replacing a chainsaw, “measuring size” is a commonly overlooked yet crucial step. Whether you're a professional contractor, equipment dealer, or industrial user, accurately measuring a chainsaw’s dimensions can significantly enhance cutting efficiency and safety — while also preventing costly purchase errors and equipment wear.

This guide explains how to measure a chainsaw’s essential parts, identify correct specifications, and ensure your cutting tasks are safer and more efficient.

Why Accurate Measurement Is Important

A chainsaw consists of a guide bar, chain, and motor system — all of which are closely related to cutting performance. Incorrect sizing can lead to chain slippage, uneven cuts, or even motor bearing damage.

For B2B buyers and wholesale distributors, wrong measurements can result in wasted inventory, unnecessary returns, and poor customer satisfaction.

According to the U.S. Forest Service (USFS), “bar length determines size of material that can be effectively cut.”

This means accurate measurement is not only a technical matter but also a safety and cost-efficiency issue that directly affects long-term performance.

Main Components and Key Measurement Points

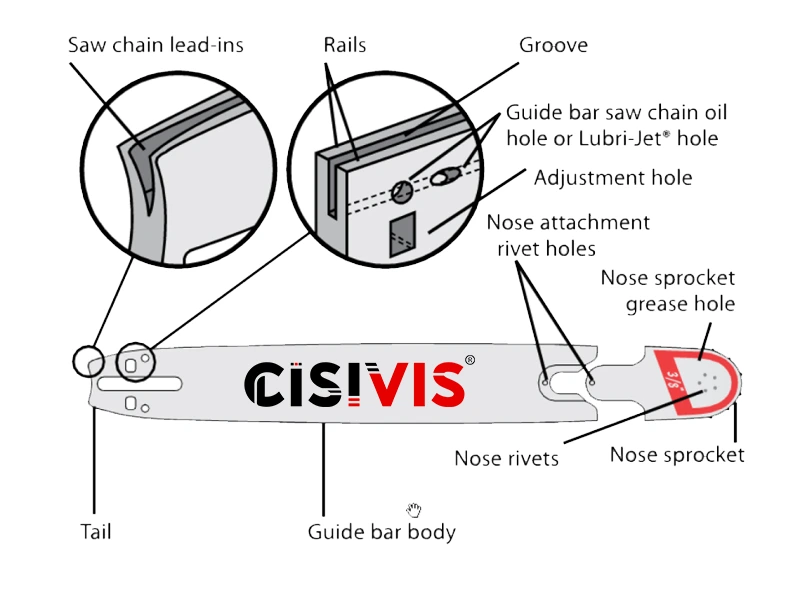

Before measuring, it’s important to understand the basic structure of a chainsaw and where key measurements should be taken:

Guide Bar (Bar Length):

The flat, elongated metal bar where the chain runs. This determines cutting capacity.

Chain:

Composed of cutting teeth and drive links. Its size must perfectly match the bar and sprocket.

Drive Sprocket and Nose Sprocket:

These affect chain tension and performance.

Powerhead (Engine):

The motor section that powers the chain.

How to Measure a Chainsaw Bar

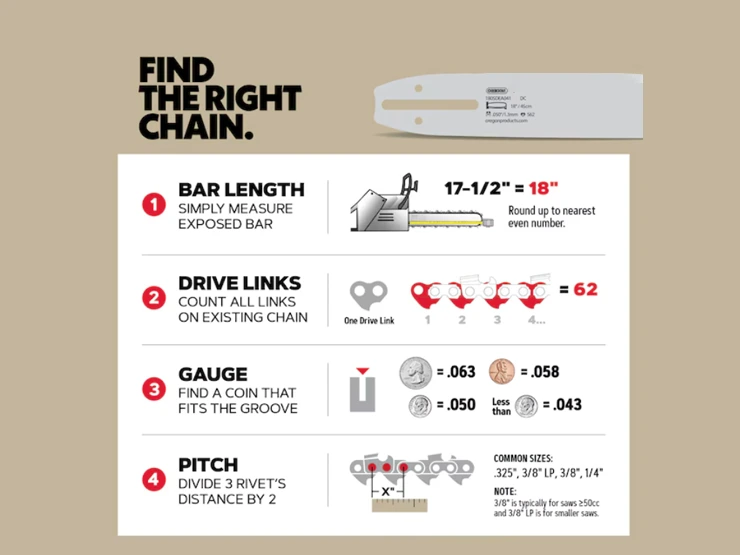

Follow these steps for an accurate measurement:

- Unplug or Remove Battery

Safety first. Disconnect the spark plug (for gas) or remove the battery (for cordless models). - Measure the Cutting Length

Use a tape measure to find the distance from the tip of the bar (nose) to the point where it enters the housing. Round up to the nearest inch—this is your “called length.” - Measure the True Bar Length

If you remove the bar completely, measure from tip to base for the actual length. - Check Chain Specifications

Record the number of drive links, pitch (distance between three rivets divided by two), and gauge (thickness of drive links).

Common Measurement Mistakes and How to Avoid Them

Even professionals occasionally make mistakes when measuring their saws. Here are common issues and how to prevent them:

- Measuring Only the Exposed Bar:

This leads to an incorrect “shorter” bar length. Always measure from the housing to the tip. - Ignoring Chain Pitch and Gauge:

Chain and bar compatibility depend on both; mismatching causes vibration and damage. - Using Wrong Units or Rounding Errors:

Always use inches, and round up only when determining “nominal” bar length.

How to Choose the Right Bar Length

Once you’ve measured your existing bar, you can decide whether to replace it with the same size or upgrade to a different length. Here’s a simple guideline:

| Bar Length (inches) | Ideal Use Case | Example Tasks |

|---|---|---|

| 10–14" | Light-duty | Trimming, pruning |

| 16–18" | Medium-duty | Cutting small trees, firewood |

| 20–24" | Heavy-duty | Felling large trees, professional forestry |

| 28"+ | Industrial | Logging, large-diameter wood |

When upgrading, ensure your chainsaw’s engine power supports the bar size. For instance, a 45cc engine is typically optimal for 18–20 inch bars.

Summary

Measuring your chainsaw accurately is essential for both safety and performance. The correct bar and chain length reduce operational strain, prevent kickback, and extend your tool’s life. Even small miscalculations can lead to dangerous outcomes or costly replacements.

For B2B buyers and suppliers, consistent measurement knowledge ensures product compatibility, inventory accuracy, and customer satisfaction. When wholesalers understand bar length and chain specifications, they can provide clients with the most suitable options for professional or industrial applications.

WHY YOU CAN TRUST CISIVIS

CISIVIS has over 6 years of experience in power tool R&D, delivering high-quality solutions worldwide. Our 3,000 m² factory, equipped with advanced machinery and strict quality control, ensures precision, efficiency, and a daily output of over 10,000 units for reliable bulk order fulfillment.

Our product portfolio includes a full range of power tools, including cordless drills, impact drills, impact wrenches, angle grinders, circular saws, jigsaws, chainsaws, lawn mowers, car washers, laser levels, cordless trimmers, polishers, paint sprayers, heat guns, and more. We also offer OEM/ODM services to meet diverse market needs.